hardness test in pharmaceutical industry|tablet hardness test wiki : solutions Hardness testing is an essential aspect of quality control in pharmaceutical industries. In this process, a load is applied to the tablet and the force that causes the tablet to break, known as the 'hardness', is measured. Resultado da 113. Mulher Chupando A Buceta Da Outra Quer ver o melhor conteúdo pornô do Brasil? Acessar os melhores vídeos e filmes pornô em HD .

{plog:ftitle_list}

Resultado da 26 de out. de 2023 · Get the latest version. 1.84. May 4, 2020. Advertisement. Five Nights at Freddy's is a first-person horror game in which players take .

Hardness testing is an essential aspect of quality control in pharmaceutical industries. In this process, a load is applied to the tablet and the force that causes the tablet to break, known as the 'hardness', is measured. The breaking force of tablets is commonly called “hardness” in the pharmaceutical literature; however, the use of this term ismisleading. Tablet breaking force measures the mechanical integrity of tablets, which is the force .

Universal test: A test that is considered potentially applicable to all new drug substances, or all new drug products; e.g., appearance, identification, assay, and impurity tests.Tests Frequency of Testing Each batch of medicinal product marketed must comply with all the specifications defining its expected quality level, regardless of the testing plans envisaged, or confirmed after experience. Testing may be chemical, physical, pharmaceutical, microbiological or biological. 1.5 Acceptance limits

Here you can read Pharmaceuticals Standard Operating Procedures (SOP), Guidelines, Method of Analysis, Test Procedures, Instruments Calibrations and Validation. Home; Quality Control; . CAUTION: – Do not . Capsule hardness testing is crucial for ensuring the quality and safety of pharmaceutical products. The CHT-01 Capsule and Softgel Hardness Tester offers precise measurement and control over the.

Hardness testing after brief exposure (30 seconds) to a small quantity (for example, 1 mL) of human simulated saliva may provide data that could be used to support the hardness specification.In the fast-paced pharmaceutical industry, maintaining high-quality standards is crucial for success. Hardness testing is a vital component in the development, production, and final testing of pharmaceutical products within the R&D and QC laboratories. The tablet hardness Tester is a critical criterion to guide product development and a quality-control parameter, as tablets .

Throughout the pharmaceutical industry, friability testing has become an accepted technology and the instrument used to perform this process is called Friabilator or Friability Tester. The mechanical strength of tablets or granules can be determined by their hardness and through this test. Understanding Friability Test Equipment

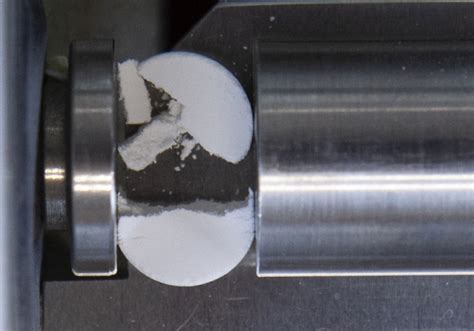

Pharmaceutical tablet hardness testing (or more correctly known as diametral/diametrical crushing strength) is a way of measuring the quality of tablets. Merlin uses tablet hardness testing to calculate the tensile strength of tablets to assess the manufacturability and compactibility of formulations. The breaking force of tablets is commonly called “hardness” in the pharmaceutical literature; however, the use of this term is misleading according to USP. Certainly, tablets require a definite amount of hardness to withstand mechanical shocks of handling in manufacture, packaging, and transportation without affecting the disintegration . Quality control is a critical component of the pharmaceutical industry, focused on ensuring that pharmaceutical products meet established quality standards, are safe for consumption, and provide the intended therapeutic effect . Physical Tests: Discuss various physical tests, such as hardness, friability, and disintegration, used to assess . Figure 4: Fracture test on tablet (CT3 Analyzer, Brookfield Engineering). Fracture test. The fracture test is accomplished by driving a smaller hemispherical ball probe into the flat surface of a solid tablet (see Figure 4).A suitable probe deformation distance must be chosen to avoid base effect, which is the external influence of the substrate surface on which the tablet is .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

hard drive test surface scan failed

what is hardness testing

In-Process Quality Control Tests: Quality in the pharmaceutical industry has become a very important and sensitive issue. Since the world has gathered together to unite its practices, guides, and the launching of the Food and Drug Administration (FDA) current good manufacturing practices (cGMP) for the 21st century – there has been a growing awareness of . How to Measure Tablet Hardness. Conventional testing measured only the point force at which tablets snap, but crush (diametral compression using a cylinder probe) testing using a Texture Analyser - particularly for controlled-release products provides valuable information about the likely performance of the tablet. Whilst capable of breaking up .

To ensure adherence to certain minimal chemical and microbiological quality standards, water used in the production of drug substances or as source or feed water for the preparation of the various types of purified waters must meet the requirements of the National Primary Drinking Water Regulations (NPDWR) (40 CFR 141) issued by the U.S. Environmental Protection .The purpose of this SOP is to provide detailed guidelines for the calibration and verification of the hardness tester in pharmaceutical manufacturing. Calibration and verification ensure the accuracy and reliability of hardness measurements, ensuring compliance with regulatory requirements and maintaining the highest standards of product .Tablet hardness is tested in the pharmaceutical industry to assure that a medication in tablet form can withstand the manufacturing and shipping processes without breaking. A hardness tester might apply pressure directly to the tablet. A snap or bending test might also be conducted. What is the name of the tab let hardness tester for tablets?

Tablet hardness testing plays an important role in pharmaceutical product development and quality control. In the race to streamline tablet hardness analysis, Advantest combines speed, simplicity and increased precision with innovative and non-destructive terahertz (THz) metrology. Read how THz spectroscopy evaluates tablet hardness and other attributes such as layer .

4.5.4. Record the hardness value displayed on the Tablet Hardness Tester for the measured tablet. 4.5.5. Repeat the measurement process for the desired number of tablets, as per the specified test requirements. 4.6. Calculation and Interpretation of Results: 4.6.1. Calculate the average hardness value for the tested tablets. 4.6.2.Key Factors Influencing Measured Tablet Hardness Author: Pharmaceutical Networking Subject: Key Factors Influencing Measured Tablet Hardness. Measuring tablet hardness (breaking force) plays a vital role in defining doasge form with optimum physical characteristics and testing Keywords: Tablet, Hardness, testing Created Date: 6/29/2012 12:44:52 PM Yes, this is correct. There has never been a test for nitrates for USP waters. The heavy metals test on USP waters was deleted in 1996. The pH test was deleted in 1998. [Note - There is a pH measurement (not a test) as a part of Stage 3 test for Water Conductivity <645>, but this is still a conductivity limit test]. Note that you cannot fail .

The term tablet hardness is commonly used in the pharmaceutical and nutraceutical industry. However, Tablet hardness is somewhat misleading in that hardness is more accurately defined as the ability of a material to resist the penetration of a probe. Found in USP Chapter <1217> “Tablet Breaking Force” is the preferred term now used in the . The United States Pharmacopeia (USP) outlines specific standards for tablet hardness testing, ensuring consistency and reliability across the pharmaceutical industry. These standards dictate the procedures and criteria for assessing the breaking force of tablets, crucial for maintaining quality and compliance.

Standard Operating Procedure for Tablet Hardness Testing Purpose The purpose of this SOP is to provide clear guidelines for the accurate and consistent measurement of tablet hardness in pharmaceutical manufacturing. Tablet hardness testing is a critical quality control parameter that ensures the tablets meet the required specifications and maintain their structural integrity .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its . What is hardness test in pharmaceutical industry? Pharmaceutical tablet hardness testing (or more correctly known as diametral/diametrical crushing strength) is a way of measuring the quality of tablets. Merlin uses tablet hardness testing to calculate the tensile strength of tablets to assess the manufacturability and compactibility of .

tablet hardness testing tool

The ERWEKA TBH 425 is a tablet hardness and combination tester for half-automatic measuring of up to 10 samples. The samples are inserted in a star-shaped feeder and then automatically transported to the test station. Depending on the device model, automatic measurement can be taken for tablet ha.

hard drive test tool ac

webBratty Sis. Step Sisters Friend Wants My Cock After Cleaning It! 4.7M 98% 14min - 720p. BRATTY SIS LANA RHOADES BIG ASS BOUNCING ON MY COCK S5. 3.3M 100% .

hardness test in pharmaceutical industry|tablet hardness test wiki